Custom Search

Wednesday, September 26, 2012

Pyrometer is a device

which uses the relationship between the electromagnetic radiation emitted by a

body and the temperature of this body. In order to better understand the

phenomenon which forms the basis of pyrometry, it is useful to explain the

concept of the blackbody, and the

differences between it and real objects.

The term blackbody is ideal, and designates a

body which radiates more electromagnetic

energy for all wavelengths intervals than any other body of the same area and

at the same temperature, and absorbs all the radiation it intercepts. Fig.1 presents one of the classical

blackbody model.

Figure 1. A classical blackbody model.

The temperature of the

blackbody determines the nature and extent of such radiation. Stefan-Boltzmann’s law says, that

the blackbody with a finite absolute temperature (T)

emits radiant (ie, in all directions) electromagnetic radiation (EMR) per unit

area of this blackbody and per second with intensity which is proportional to T4,

according to an equation:

ET = σ * T4, (2)

where,

ET - total EM energy

emitted by the blackbody in all directions per unit area (1.m2) and per unit time

(1,s),W/m2;

σ -

Stefan-Boltzmann’s constant, equal to 5.67051*10-8, W/(m2*K4);

T - an absolute temperature of the blackbody, K.

Fig. 2 shows the relationship between EMR emitted by a perfect blackbody as a

function of temperature. The area under these curves is equal to the total

energy (emitted by a black body) per second per unit area. This body at low

temperatures emits EMR in the region of long wavelengths. This region spreads

from far-infrared to microwave region (5 mm < λ < 100 mm, where λ is the

wavelength in mm, 10-6

m). With increasing the blackbody temperature, the emission peaks move into the

region of shorter wavelengths. At very high temperatures the blackbody emits in

the near visible wavelengths region. Visible region corresponds to the

wavelengths from 0.7 mm (red) through

0.62 mm (orange), 0.58 mm (yellow), 0.53 mm (green), 0.47 mm (blue) to 0.42 mm (violet).

Real

objects emit and absorb less EMR than blackbodies, and this difference is

dependent on the wavelength, so nonblackbodies can not exactly follow

relationship shown in Fig. 2. For

this purposes corrections should be used, otherwise, the apparent temperature

will be lower that the actual temperature. Also, it is necessary to take into

account the loss of emitted radiation when it passes through the media between

the emitting body and a measuring instrument.

Figure 2. EM radiation emitted by the blackbody at various temperatures.

There are two types of

pyrometers: optical (monochromatic or

narrowband) and radiation (total

radiation or broadband) pyrometers. The last devices originally were called

radiation pyrometers, then radiation thermometers, and more recently infrared

thermometers. However, the first their name (radiation pyrometers) is still

widely used at present. These devices have high accuracy of ±0.01 °C as a standard instruments,

and from ±0.5 to ±1% for industrial purposes.

a). Optical pyrometers, sometimes referred

to as brightness thermometers,

generally involve wavelengths only in the visible part of the spectrum. When

the temperature of the body increases, so does the intensity at any particular

wavelength. If two bodies have the same temperature, then intensities of those

two objects are equal. In this type of a pyrometer the intensity of a certain

wavelength of a heated body is compared with that of a heated platinum filament

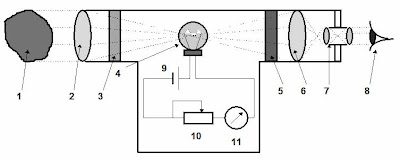

of a lamp (see Fig. 3 ).

Figure

3. An optical pyrometer.

An object 1

which temperature is to be measured, emits electromagnetic radiation with

intensity proportional to its absolute temperature. This radiation passes

through lens 2 and red optical filter 3. Optical filter picks out only the

desired wavelength - red. Then radiation focuses on the platinum filament of a

lamp 4,

and passes through another filter 5, lens 6, viewing system 7.

The viewer 8 sees the platinum filament superimposed on an image of the

object 1. When the temperature of the filament is low comparing with

that of the object, the viewer sees the filament as a dark line on the bright

background image of the object. The lamp 4 is connected in series with an

electrical battery 9, a variable resistor 10 and an ampermeter 11.

By reducing the resistance of the resistor an electrical current passing

through the filament increases. So does the temperature of the filament and its

brightness. For a certain value of an electrical current (corresponded to a

certain value of an object temperature), the brightness of the platinum

filament will match the brightness of the object 1. At this setting the

viewer cannot distinguish between the image of the object and the filament. At

this time the measurement of temperature is performed. The scale of the

ampermeter is calibrated in the units of temperature.

The lower temperature limit

for optical pyrometers is determined by the temperature at which objects become

visible in red (about 225 °C). However,

there are devices which are able to measure even lower temperatures down to -50

°C. The upper

limit varies from 600 to 3000 °C, and is limited

by the melting point of the platinum filament. An accuracy is typically varied

from ±5 to ±10 K.

b). Radiation pyrometers, being very simple

and cheap, use an exponential relationship between a total emitted EMR energy

and given temperature. In radiation pyrometers (see Fig. 4) EMR energy emitted at infrared (2.5 < l < 20 mm) to visible wavelengths

(0.42 < l < 0.7 mm) from an object 1

is focused by a spherical reflector 2 on a series of micro-thermocouples

attached to a blackened platinum disc 3. The radiation is absorbed by the

disc, which temperature is increased, so does thermal electromotive force U

developed by the series of thermocouples. This thermal electromotive force is

proportional to the temperature of hot junctions of thermocouples, and,

finally, to the temperature of the object 1. The advantage of these pyrometers

is that their operation slightly depends on the wavelength.

Figure 4. A total radiation pyrometer

The lower limits for

radiation pyrometers vary from 0 to 600 °C, the upper limits vary

from 1000 to 1900 °C. The accuracy

varies from ±0.5 to ±5 K, depending on cost. They

are widely used for temperature measurements in metal production facilities,

glass industries, semiconductor processes, etc.

Article Source:: Dr. Alexander Badalyan, University of South Australia

Thermistors Basics

If semiconductors or

heat-treated metallic oxides (oxides of cobalt, copper, iron, tin, titanium,

etc.) are used as the materials for producing temperature sensitive elements,

then these temperature transducers are called thermistors (the name is derived from the term of ‘thermally

sensitive resistor’). These oxides are compressed into the desired shape from

the specially formulated powder. After that, the oxides are heat-treated to

recrystallise them. As the result of this treatment the ceramic body becomes

dense. The leadwires are then attached to this sensor for maintaining

electrical contact.The following relationship

applies to most thermistors:

Rt = R0*eB*(1/T - 1/T0) (1)

where,

RT0 - resistance of thermistor at reference temperature T0, K, Ohm;

Fig. 3.15 shows relationship between temperature and resistance for a thermistor.Thermistors have negative thermal coefficient of electrical resistance. It means that when temperature increases the electrical resistance of thermistor decreases. They have greater resistance change (this is an advantage) compared with RTD in a given temperature range. For example, if we compare what change in resistance will be caused by variation of temperature in 1 °C for Platinum and Copper RTD and for thermistor (see Fig. 2) in the temperature range from 273.15 to 423.15 K (ie, from 0 to 150 °C), we will obtain the following values:

All the discussed above instrumentation for temperature measurement refers to contact-type devices, because their sensitive elements are immersed in the measuring media. When dealing with temperatures above 1500 °C, contact-type temperature measuring devices are not applicable, because irreversible changes occur in metals which form their sensitive elements. It is possible to perform non-contact measurement of temperature by optoelectronic transducers.

Article Source:: Dr. Alexander Badalyan, University of South Australia

Labels:

Basics,

Sensors,

Temperature

Subscribe to:

Comments (Atom)

Basics of Instrumentation & Control

Pressure

Flow

Level

Temperature

Analytical Instrumentation

Labels

Analytical Instrumentation

(7)

Automation

(4)

Basics

(48)

Control elements

(2)

DCS

(1)

Flow

(27)

Flow Meters

(22)

Instrumentation Career

(2)

Level

(19)

P and I Diagram

(1)

PLC

(2)

Pressure

(12)

Process Control

(5)

Process Control Systems

(6)

SCADA

(2)

Sensors

(7)

Temperature

(17)

Transducer

(17)

Virtual Instrumentation

(1)